Highland Park Decorative Concrete Pros

Get concrete designed and built for Highland Park's unique climate and building codes. We properly grade for drainage, thoroughly compact subbases, and install air‑entrained, low w/c mixes with fiber additives, calculated joint positioning, and proper concrete cover per ACI/IDOT standards. Count on superior freeze‑thaw durability, salt-wear prevention, and slip‑resistant finishes for concrete surfaces including driveways, patios, and walkways. Our service covers permits, engineer-stamped plans, inspections, and Gantt‑tracked project schedules, featuring documented mix designs, pour tickets, and RFIs. We conduct repairs and overlays using strict quality control and curing standards. Learn how our thorough process ensures lasting value.

Core Findings

- Local Highland Park experts: oversee regulatory compliance and inspection processes, offering certified construction documents and detailed weekly updates on quality, progress, and safety measures.

- Durable, weather-resistant concrete: incorporating air-entrained mixtures, reduced water-cement content, supplementary cementitious materials, optimal curing methods, frost resistance measures and salt attack mitigation, and sun-proof, anti-slip sealers.

- Precise site preparation and drainage: confirmed elevations, 2% slopes, consolidated subgrade, geofabrics, vapor barriers, and utility/access corridor planning to avoid settling and dampness concerns.

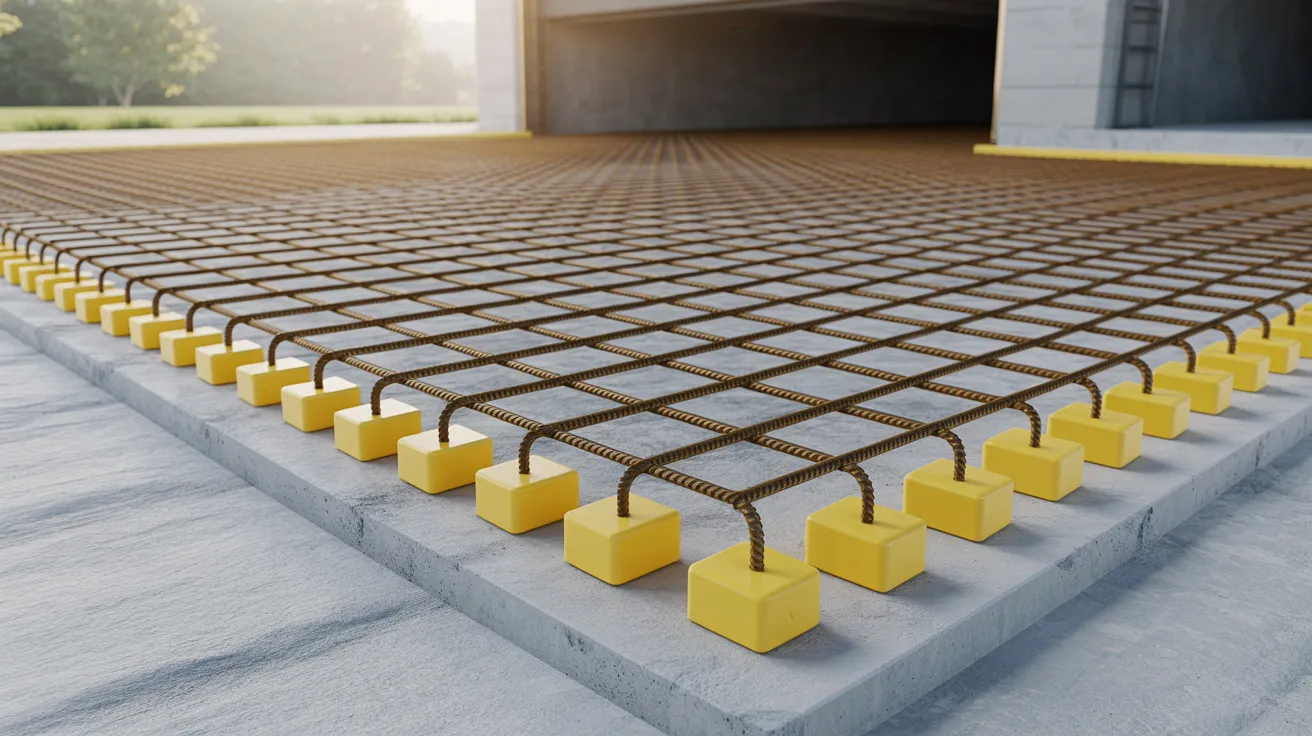

- Strong, code-compliant slabs: #4/#5 rebar on chairs, control and expansion joints following ACI/ASTM standards, proper concrete cover, dowels and anchors, and temperature barriers to minimize movement and thermal bridging.

- Transparent project planning and expenses: We provide detailed project timelines and schedules, instant status reports and inspection details, itemized estimates broken down by units and quantities, and shared logs for project tracking including submittals, tickets, RFIs, and change orders.

The Importance of Local Knowledge in Highland Park

Even though concrete standards are the same across regions, Highland Park's climate, soil profiles, and municipal codes call for local expertise to build right the first time. You need a contractor who reads expansive clay, knows about freeze‑thaw cycles, and specifies mixes, reinforcement, and jointing that fulfill local performance criteria. With neighborhood knowledge, a pro maps drainage patterns, utility easements, and right‑of‑way constraints that impact slab thickness, base prep, and placement timing. They also simplify permit navigation, submitting stamped plans, arranging inspections, and complying work with Highland Park ordinances and IDOT references. You'll eliminate delays, rework, and violations because aspects like air‑entrainment, curing windows, and salt‑exposure mitigation are handled up front. Local expertise translates code into practical applications-on schedule, within parameters, and inspection-ready.

Driveway Design and Installation

The process starts with site grading essentials to control slope requirements, frost heaving, and proper drainage. Then, choose the right reinforcement—fiber, rebar, or welded wire mesh to minimize cracking and support vehicle loads per local specifications. The last step is choosing finishes—broom, exposed aggregate, or sealed smooth that balance safety, appearance, and upkeep.

Site Grading Fundamentals

Before concrete installation begins, correct site grading forms the groundwork for a durable, code-compliant driveway. The existing grade levels are checked, set finish grades, and establish slopes-generally 2%-to direct water away from structures and to designated drainage points. The base layer is shaped to eliminate low spots, then compact the Pioneer Paving & Landscaping soil to proper density specifications, verifying outcomes through testing. Stable subgrade prevents settling, fractures, and water pooling.

Drainage swales are integrated alongside property lines to capture runoff, tying them into catch basins or curb inlets according to municipal specifications. Surrounding areas are secured by regulating drainage and preventing erosion with silt control measures. Proper clearances are maintained near garages, sidewalks, and utilities, while checking setback requirements. After grading is completed, staking and inspection comes before foundation work and pour coordination.

Strengthening and Surface Treatments

Once grades are verified and subgrade stability is confirmed, select reinforcement and surface treatments that comply with Highland Park standards and project load demands. Select #4 or #5 bars at 18-inch centers, or welded wire mesh per specifications, and tie intersections to maintain proper cover. Reinforcement must maintain a minimum 2 inches of bottom cover and clear spacing from expansion joints, utilities, and driveway apron dowels. Place steel chairs, not stones, to support steel. Anchor driveway-to-garage junctions with epoxied dowels where specified.

Pour concrete at the designated slump, compact edges, and form control joints at 10-12 feet spacing or 24-30 times slab thickness within a 6-12 hour window. Execute finishing techniques that enhance traction and durability: broom finish for drive lanes, combination troweled and broomed edges, and curing compound or wet cure for a week-long duration.

Patios, Pool Decks, and Outdoor Living Spaces

You're looking for outdoor spaces that last maintaining a clean look and work year-round. We utilize resilient outdoor materials-concrete reinforcement, fiber enhancement materials, and protective sealants-that resist wear, staining, and crack formation. For pool decks, we install anti-slip texturing and finishes that increase wet-condition grip without compromising drainage and comfort.

Durable Patio Materials

Stone, concrete, and composite materials are essential for outdoor living spaces, pool surrounds, and patios that need to endure environmental exposure, foot traffic, and temperature cycles. You need solutions providing proven durability and environmental protection. Select air-entrained concrete with fiber reinforcement and appropriate subbase installation to reduce wear. Install long-lasting paver systems with protective joint filling to direct runoff. Choose sustainable composite materials featuring sustainable materials with UV inhibitors that resist degradation or need frequent maintenance.

Ensure proper drainage with 1/8-1/4 inch per foot decline extending from structures, along with perimeter edging and geotextile separation over compacted aggregate. Make sure to use sealers specifically rated for handling deicing salts and UV exposure. Demand ASTM/ACI compliance and detailed warranties to guarantee optimal long-term performance.

Slip-Resistant Pool Surfaces

Beyond material durability, pool deck surfaces need to safeguard swimmers from slip hazards. The deck surface must combine safety compliance with attractive design. We select non-slip surface treatments with tested slip resistance ratings, apply textured coatings for dependable traction in damp conditions, and refine joint layouts to minimize trip points. We also integrate drainage solutions-effective gradients, linear drains, and subtle water routing-to move water off the surface quickly and minimize biological buildup.

We provide UV-stable sealers that resist chlorine and salt, plus temperature-controlled surfaces that reduce heat absorption. We repair spalls, refinish worn concrete, and install broadcast aggregates in locations additional grip is needed. Control joints, edge treatments, and handrail anchors are fitted per code. The final product is a hassle-free, safe, and appealing pool deck built for daily use.

Walkways, Sidewalks, and Property Enhancement Solutions

A damaged or irregular walkway can diminish your home's curb appeal and safety, expertly constructed paths and walkways directly improve appearance and usability. We evaluate grades, drainage, and local Highland Park regulations, then install proper foundation, formwork, structural support, and movement joints for long-lasting, secure pathways. You have the option of textured, decorative, or patterned surfaces that balance traction and style.

To improve safety and adherence, we implement well-defined curb markings at junctions and accessibility ramps as required. Well-planned landscaping elements establish distinct perimeters, prevent soil encroachment on concrete, and channel walking paths. Low-profile illumination, protected boundaries, and well-maintained joint spaces keep maintenance manageable. You receive a unified entrance sequence that guides visitors, withstands the elements, and enhances your property's curb appeal without excessive construction.

Foundations, Slabs, and Structural Concrete

Whether you're constructing new foundations or stabilizing existing structures, we specialize in designing and pouring foundations and slabs that fully comply with Highland Park codes, soil conditions, and structural loads. We thoroughly evaluate geotechnical reports, recommend appropriate soil stabilization as required, and outline the proper rebar, post-tensioning, or grade beams to control movement and cracking. We deliver accurate elevations, vapor barriers, and correctly installed control joints in accordance with ASTM and ACI standards.

For slabs-on-grade, we evaluate soil compaction, moisture barriers, and drainage patterns from the foundation. We determine optimal mixes that deliver strength, longevity, and weather resistance, and we oversee curing conditions to meet specified strength requirements. For basement and structural components, we install formwork, anchor bolts, and dowels according to specifications. We incorporate thermal insulation where specified, enhancing thermal performance without affecting structural stability.

Decorative Concrete Options: Stamping, Staining, and Polishing

For entrances and outdoor living areas, you can transform concrete with stamped, stained, or polished finishes that meet Highland Park codes and performance expectations. You'll select design elements, materials, and grip ratings that conform to local specifications and use zones.

When working with stamped concrete, we establish mix designs, control-joint layouts, and texture layering to mimic masonry, brick patterns, or wood grain while maintaining proper water drainage and cold-weather resistance. Color integration and protective sealing maintain color integrity and prevent sun fading.

When dealing with stained floors, we evaluate substrate moisture levels, determine whether to use acid-based or water-based treatments, and apply densification products to improve wear resistance. Edge terminations and transitions remain compliant with ADA standards.

In polished concrete applications, we establish cut sequences, clarity-of-image targets, and guard applications. You'll receive a long-lasting, simple-to-maintain surface that delivers both function and sophistication.

Repair, Resurfacing, and Maintenance Services

Minor surface defects can develop into serious structural concerns if ignored, so we thoroughly assess underlying problems and perform code-compliant repairs customized for Highland Park requirements. We strengthen substrates, rebuild profiles, and restore proper drainage to protect adjacent structures and utilities. For narrow, non-moving fractures, we apply crack injection to reestablish monolithic performance and prevent moisture infiltration. Where material separation appears, we mill and resurface with bonded materials, maintaining correct slopes and control-joint layout.

You'll receive a maintenance schedule that covers regular cleaning, repairs, and protective treatments to reduce damaging elements and wear. We maintain detailed records of all methods and materials used, offer warranty options, and verify compliance with municipal standards. Our methodical process increases longevity and reduces lifecycle costs.

Materials, Techniques, and Weather-Ready Practices

Such maintenance procedures only work effectively when they are combined with suitable mix formulations, placement procedures, and weather management protocols suited to Highland Park. Initial requirements include air-entrained mixtures with reduced w/c ratios, supplementary cementitious materials for longevity, and ASTM/ACI‑compliant admixtures for set control. For structural elements, detail adequate reinforcement protection and joint placement per ACI 318 and ACI 360. Where cold formed concrete assemblies are detailed, synchronize anchor placement, curing methods, and fastener specifications to minimize crack formation.

You install climate‑regulated base layers, utilize vapor barriers where required, and finish with slip‑resistant textures. Moisture retention covers, insulated forms, and climate-controlled environments keep hydration at specified parameters. You implement thermal bridging mitigation for slabs, balconies, and edges using thermal breaks. De‑icing chemical limits, protective coatings, and timing of cuts minimize scaling and joint raveling.

Straightforward Scheduling, Pricing, and Project Management

Predictable results stem from well-defined expectations, so we build transparency into all steps: a comprehensive baseline schedule with critical path milestones, crew assignments, and inspection checkpoints; a complete scope specifying inclusions/exclusions; and a detailed estimate connected with quantities, unit rates, and contingencies. You'll receive precise estimates that specify assumptions, alternates, and allowances, so pricing matches drawings, specs, and applicable codes. We publish a Gantt schedule and deliver real-time updates when environmental issues, inspections, or utility locates affect sequencing. You can access submittals, mix designs, and pour tickets in a common log. We record RFIs, change orders, and field directives with implications to time and cost. Weekly check-ins validate progress, safety, testing, and punch action items-guaranteeing accountable execution without surprises.

Common Inquiries

Are You Properly Licensed, Bonded, and Insured for Highland Park Operations?

We maintain complete licensing, bonding, and insurance coverage for Highland Park. Our licensed experts understand local regulations and permit requirements. Upon request, we'll share our insurance and bond documentation, including license numbers for verification. Our coverage includes general liability and workers' compensation insurance, and you'll be added as a certificate holder. You can verify our status with the city or state portals. Our focus remains on compliance, safety, and clear documentation.

What Warranties Do You Offer on Materials and Workmanship

You receive clear and comprehensive warranty coverage for Materials and Workmanship. Here's the proof: strong guarantees show our commitment. We support materials based on manufacturer terms-typically 2-5 years-fully documented and transferable as appropriate. We offer a 1-year warranty, protecting against problems with installation and finishing, in compliance with local codes and ASTM standards. You'll receive detailed warranty documentation, specifying warranty terms, exclusions, and claims details. Should issues arise, get in touch with us; we'll assess, fix, and confirm proper resolution.

What's Your Process for City Permits and Inspections?

We take care of all permits and inspections for you. We prepare fully compliant documentation, process permit applications, and follow permit progress with the city. We handle inspection scheduling, are present for every inspection, and address feedback promptly. You'll get notifications at each important stage-submission, approval, preliminary, and completion. Should modifications be necessary, we immediately provide revised paperwork. We maintain all necessary permits and insurance required by the municipality, guaranteeing your project proceeds smoothly and according to regulations.

Can You Provide Recent Local References and Project Photos?

Absolutely. We'll provide a curated list of latest projects within 5 miles, complete with dates, scopes, and client testimonials. Since 63% of homeowners feel dissatisfied about hiring without seeing proof, we provide professional project photos, before-and-after sets, and material specs. We provide contactable references, permit numbers, and inspection approvals for verification. When asked, we can arrange site walk-throughs and provide a secure link to a gallery organized by project type, code requirements, and finish options.

What Is Your Policy for Change Orders and Unforeseen Issues?

We generate written change orders for modifications to project scope, priced transparently and requiring your approval before proceeding with work. Unforeseen issues trigger contingency planning: we assess underlying factors, propose code-compliant remedies, update timeline and cost, and maintain detailed records. If conditions affect safety or building stability, we suspend activities until you authorize the fix. We document deviations, keep detailed daily records, and arrange necessary inspections to maintain project oversight, conformity, and reliability.

Conclusion

You've got goals for your property, and we've got the proven approach to make them reality. From decorative surfaces to driveways, you'll enjoy regional experience, proven methods, and climate-smart solutions. We'll handle planning, implementation, and upkeep with detailed planning, transparent pricing, and steady communication-no guesswork. Whether it's a new foundation or a refined outdoor space, we maintain quality throughout. Let's turn plans into solid ground-durable as stone, flawless in finish.